DELEKS S.r.l.

Via Industriale, 23

25028 Verolanuova (BS) Italy

Tel. 030 6585725

Mail info@deleks.com

Lun - Ven: 9.00-13.00 / 14.00-18.00

Tractor mounted Bio Shredder with Hydraulic Feed

DETAILS

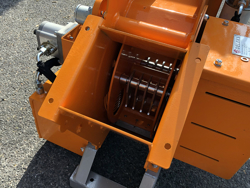

Tractor-mounted PTO wood chipper DELEKS® DK-1300, equipped with an independent hydraulic system and combined drum cutting system, designed for producing wood chips from branches, brushwood and pruning residues with foliage.

Three-point mounted machine for tractors with 540 rpm PTO.

PRODUCT DESCRIPTION

The DELEKS® DK-1300 is a drum wood chipper for tractors designed for agricultural and forestry applications, particularly suitable for processing pruning residues with leafy branches.

-

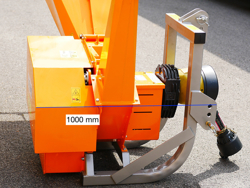

The machine operates via the tractor PTO and is equipped with a fully independent hydraulic system with its own oil tank, requiring no hydraulic connections to the tractor.

-

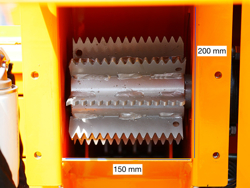

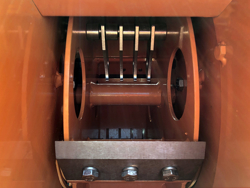

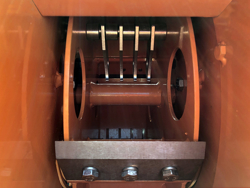

The cutting system has a dual function: the internal drum combines two chipping blades with two rows of hammers, allowing the machine to work both as a wood chipper and as a shredder for further reduction of chips and foliage.

-

Material feeding into the cutting chamber is handled by a hydraulically driven feed roller, ensuring constant and controlled material intake.

-

Feed roller speed is manually adjustable via a dedicated valve, allowing adaptation to the type and hardness of the processed wood.

-

Thanks to feed speed regulation and the combined cutting system, the machine produces uniform and regular wood chips suitable for biomass boilers.

APPLICATION

Suitable for shredding:

-

dry wood

-

green wood

-

branches and brushwood

-

pruning residues with foliage

Maximum processing diameter: 10 cm.

The produced wood chips are uniform and suitable for efficient combustion in wood chip boilers.

The machine is not suitable for shredding maize, straw, alfalfa or similar herbaceous materials.

COMPATIBILITY

The DK-1300 wood chipper is compatible with tractors equipped with:

-

540 rpm PTO

-

Category 1 three-point linkage

Compatible with most compact and isodiametric tractors, including Kubota, Antonio Carraro, Goldoni, New Holland, Landini, Pasquali, Valpadana and equivalent models.

TECHNICAL FEATURES AND ADVANTAGES

-

Combined cutting system: drum with 2 blades + 2 rows of hammers

-

Hydraulic feed roller for easier and faster operation

-

Independent hydraulic system with dedicated oil tank

-

Manual adjustment valve for feed roller speed control

-

Safety control bar for immediate stop and reverse of the feed roller

-

Easy access to the cutting chamber for maintenance and blade/hammer replacement

-

Discharge chute adjustable through 360°

-

Foldable hoppers for reduced transport width (1150 mm)

-

CE-approved PTO shaft included

CERTIFICATIONS – WARRANTY – SERVICE

-

Machine compliant with the CE Machinery Directive

-

Equipped with safety protections

-

2-year warranty

-

Technical support and spare parts availability guaranteed

DOCUMENTATION SUPPLIED

-

EC Declaration of Conformity

-

Operation and maintenance manual

-

Invoice or fiscal receipt

CHARACTERISTICS

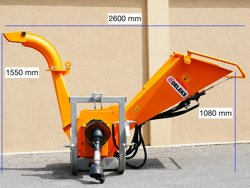

| Characteristic | Units metric | Units US |

|---|---|---|

| Weight | 225.0 kg | 500.0 lb |

| Tractor Power Range | 18 - 50 Hp | 18 - 50 Hp |

| 3 point linkage | Cat. 1 (ø 19.0-22.0mm) | Cat. 1 (ø 19.0-22.0mm) |

| Transmission | Hydraulic system | Hydraulic system |

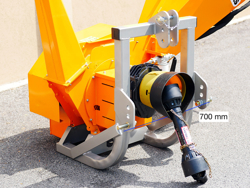

| Distance between pto attachment and base | 500.0 mm | 19.70 in |

| Pto shaft | CE 4x800 mm + shear bolt | CE 4x 2.60 ft + shear bolt |

| Working Efficiency | 8-9 m3/h | 25-30 sq ft/h |

| Cutting System | Drum with 2 blades + 8 hammers | Drum with 2 blades + 8 hammers |

| Chipped material size range | 5.0 - 10.0 mm | 0.2 - 0.4 in |

| PTO Turning Speed | 540 r/min | 540 r/min |

| Transmission V-Belts quantity | x | x |

| Safety System | Stop and Start lever | Stop and Start lever |

| Roller: quantity | 1 | 1 |

| Roller: width | 150.0 mm | 5.90 in |

| Roller: drive system | Hydrauilc, no Belts | Hydrauilc, no Belts |

| Outlet Tube Sizes | 360° | 360° |

| Maximum cutting diameter | 80.0 - 100.0 mm | 3.15 - 3.94 in |

| Outlet hight | 1550.0 mm | 5.0 ft |

| Packing sizes | 1250.0*110.0*2200.0 mm | 3.61*3.22*5.58 ft |

DETAILS

CLOSETractor-mounted PTO wood chipper DELEKS® DK-1300, equipped with an independent hydraulic system and combined drum cutting system, designed for producing wood chips from branches, brushwood and pruning residues with foliage.

Three-point mounted machine for tractors with 540 rpm PTO.

PRODUCT DESCRIPTION

The DELEKS® DK-1300 is a drum wood chipper for tractors designed for agricultural and forestry applications, particularly suitable for processing pruning residues with leafy branches.

-

The machine operates via the tractor PTO and is equipped with a fully independent hydraulic system with its own oil tank, requiring no hydraulic connections to the tractor.

-

The cutting system has a dual function: the internal drum combines two chipping blades with two rows of hammers, allowing the machine to work both as a wood chipper and as a shredder for further reduction of chips and foliage.

-

Material feeding into the cutting chamber is handled by a hydraulically driven feed roller, ensuring constant and controlled material intake.

-

Feed roller speed is manually adjustable via a dedicated valve, allowing adaptation to the type and hardness of the processed wood.

-

Thanks to feed speed regulation and the combined cutting system, the machine produces uniform and regular wood chips suitable for biomass boilers.

APPLICATION

Suitable for shredding:

-

dry wood

-

green wood

-

branches and brushwood

-

pruning residues with foliage

Maximum processing diameter: 10 cm.

The produced wood chips are uniform and suitable for efficient combustion in wood chip boilers.

The machine is not suitable for shredding maize, straw, alfalfa or similar herbaceous materials.

COMPATIBILITY

The DK-1300 wood chipper is compatible with tractors equipped with:

-

540 rpm PTO

-

Category 1 three-point linkage

Compatible with most compact and isodiametric tractors, including Kubota, Antonio Carraro, Goldoni, New Holland, Landini, Pasquali, Valpadana and equivalent models.

TECHNICAL FEATURES AND ADVANTAGES

-

Combined cutting system: drum with 2 blades + 2 rows of hammers

-

Hydraulic feed roller for easier and faster operation

-

Independent hydraulic system with dedicated oil tank

-

Manual adjustment valve for feed roller speed control

-

Safety control bar for immediate stop and reverse of the feed roller

-

Easy access to the cutting chamber for maintenance and blade/hammer replacement

-

Discharge chute adjustable through 360°

-

Foldable hoppers for reduced transport width (1150 mm)

-

CE-approved PTO shaft included

CERTIFICATIONS – WARRANTY – SERVICE

-

Machine compliant with the CE Machinery Directive

-

Equipped with safety protections

-

2-year warranty

-

Technical support and spare parts availability guaranteed

DOCUMENTATION SUPPLIED

-

EC Declaration of Conformity

-

Operation and maintenance manual

-

Invoice or fiscal receipt

CHARACTERISTICS

CLOSE| Characteristic | Units metric | Units US |

|---|---|---|

| Weight | 225.0 kg | 500.0 lb |

| Tractor Power Range | 18 - 50 Hp | 18 - 50 Hp |

| 3 point linkage | Cat. 1 (ø 19.0-22.0mm) | Cat. 1 (ø 19.0-22.0mm) |

| Transmission | Hydraulic system | Hydraulic system |

| Distance between pto attachment and base | 500.0 mm | 19.70 in |

| Pto shaft | CE 4x800 mm + shear bolt | CE 4x 2.60 ft + shear bolt |

| Working Efficiency | 8-9 m3/h | 25-30 sq ft/h |

| Cutting System | Drum with 2 blades + 8 hammers | Drum with 2 blades + 8 hammers |

| Chipped material size range | 5.0 - 10.0 mm | 0.2 - 0.4 in |

| PTO Turning Speed | 540 r/min | 540 r/min |

| Transmission V-Belts quantity | x | x |

| Safety System | Stop and Start lever | Stop and Start lever |

| Roller: quantity | 1 | 1 |

| Roller: width | 150.0 mm | 5.90 in |

| Roller: drive system | Hydrauilc, no Belts | Hydrauilc, no Belts |

| Outlet Tube Sizes | 360° | 360° |

| Maximum cutting diameter | 80.0 - 100.0 mm | 3.15 - 3.94 in |

| Outlet hight | 1550.0 mm | 5.0 ft |

| Packing sizes | 1250.0*110.0*2200.0 mm | 3.61*3.22*5.58 ft |

Technical charts

CLOSE| Shell Spirax S2 A 80W-90: Specifications | Download PDF |

| Shell Tellus S2 MX 46: Specifications | Download PDF |