DELEKS S.r.l.

Via Industriale, 23

25028 Verolanuova (BS) Italy

Tel. 030 6585725

Mail info@deleks.com

Lun - Ven: 9.00-13.00 / 14.00-18.00

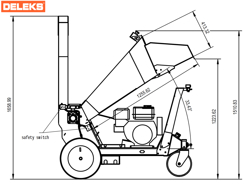

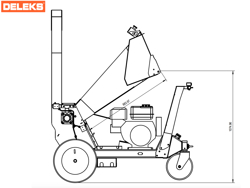

Mobile wood chipper shredder with autonomous electric drive

DETAILS

The mobile wood chipper shredder with autonomous electric drive is designed for chipping dry and green wood up to 10 cm in diameter and is equipped with a silent electric mobility system. The machine can be easily moved in gardens, parks and agricultural environments without the need for tractors or towing vehicles.

GENERAL DESCRIPTION

This machine has been developed to combine a professional chipping system with an innovative transport solution, allowing the wood chipper to be moved completely silently even on uneven terrain or in confined spaces. It is a unique solution on the market, intended for operators who require high cutting performance together with maximum mobility and operational convenience.

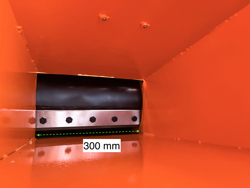

DRUM CHIPPING SYSTEM

The cutting system is based on a high-inertia central drum with a width of 300 mm and a diameter of 230 mm, equipped with 2 reversible 300 mm blades made of high-strength special steel, combined with a fixed counter-blade. This configuration ensures a clean, continuous and uniform cut, providing consistent and regular chip production on both dry and green wood.

CHIP DISCHARGE

The machine is equipped with a high, adjustable discharge chute designed to efficiently direct the wood chips into bins, trailers or compost containers. The discharge height facilitates chip collection operations, including loading onto transport vehicles.

APPLICATIONS

The machine is suitable for chipping:

-

dry wood

-

green wood

-

branches and brushwood

-

pruning residues

-

palm leaves

Maximum chipping diameter: 10 cm.

The produced chips are generally regular, approximately 1 cm in size, depending on the type and moisture content of the processed material. The machine is not suitable for shredding maize, straw, alfalfa or similar herbaceous materials.

ENGINE AND STARTING SYSTEM

The machine is equipped with a 420 cc Loncin engine with electric key start, designed to concentrate all its power on the cutting system. This solution guarantees high performance, operational reliability and continuous operation even under intensive working conditions.

AUTONOMOUS ELECTRIC MOBILITY

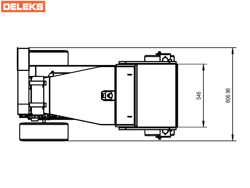

The wood chipper is mounted on an integrated four-wheel trolley, with two driven wheels and two pivoting wheels, powered by an electric motor. This configuration allows extremely smooth, precise and silent movements, making the machine particularly suitable for use in gardens, parks and noise-sensitive environments.

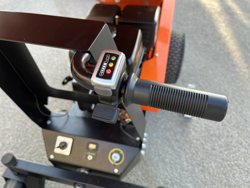

STEERING SYSTEM AND CONTROLS

The control systems are located on the two steering handles.

On the right handle are the progressive throttle, forward and reverse drive control and the battery charge status indicator, allowing real-time monitoring of the electric motor autonomy.

On the left handle there is the speed selector, allowing the operator to choose between:

-

Speed 1 (slow): 3 km/h

-

Speed 2 (fast): 6 km/h

In reverse gear, the speed is automatically limited to slow mode at 3 km/h, ensuring greater safety and control during manoeuvres.

CONTROL PANEL

At the base of the trolley there is a complete control panel including:

-

hour meter

-

key switch ON / OFF

-

reverse gear indicator light

-

operating mode selector with three positions:

-

ON chipping

-

ON charging or movement

-

OFF switched off

-

TERRAIN ADAPTATION AND STABILITY

The axle on which the two pivoting wheels on the operator side are mounted is of a floating type, thanks to a central pivot that allows the machine to follow the terrain profile even on uneven surfaces. The arrangement of the main weight components, particularly the combustion engine and the electric motor, has been designed to achieve a very low centre of gravity, improving stability, traction and safety during chipping and movement.

POWER SUPPLY AND AUTONOMY

Electric mobility is powered by a 12 V / 20 Ah battery. The autonomy at maximum continuous speed is approximately 90 minutes; under normal, non-continuous operating conditions, this allows a full working day without the need to recharge the battery.

Indicative charging time is approximately 4 hours using a standard 220 V domestic power supply.

SAFETY

The machine is equipped with a mushroom-type emergency stop button that immediately shuts down the engine in case of emergency. A safety sensor prevents the wood chipper engine from starting if the discharge chute is removed. The feed hopper can also be folded, preventing the cutting system from being exposed when the machine is parked or during transport.

BATTERY MANAGEMENT AND EMERGENCY MOVEMENT

If the batteries become discharged during field operation, the wheels can be released, allowing the machine to be pushed or towed manually to the vehicle or charging point.

CERTIFICATIONS – WARRANTY – SERVICE

Machine compliant with CE regulations and equipped with safety protections

2-year warranty

DELEKS® technical support and spare parts availability

SUPPLIED DOCUMENTATION

CE declaration of conformity

User and maintenance manual

Invoice or fiscal receipt

CHARACTERISTICS

| Characteristic | Units metric | Units US |

|---|---|---|

| Weight | 230.0 kg | 507.0 lb |

| Blades: Weight | 600.0 g | 21.16 oz |

| Transmission | V Belts | V Belts |

| Working Efficiency | 6-7 m3/h | 19.70-23.0 sq ft/h |

| Cutting System | Chipping drum with 2 blades + 1 fixed blade | Chipping drum with 2 blades + 1 fixed blade |

| Chipped material size range | 1.0 cm | 0.40 in |

| Transmission V-Belts quantity | 2 | 2 |

| Transmission V-Belts sizes | A69 - 1752x13 | A69 - 1752x13 |

| Safety System | Emergency button | Emergency button |

| Blades: Sizes | 300.0*54.0 mm | 11.81*2.16 in |

| Maximum cutting diameter | 80.0 - 100.0 mm | 4.00 in |

| Engine | Loncin 420cc 14cv | Loncin 420cc 14cv |

| Starter | E-start and Pull cord | E-start and Pull cord |

| Wheels: sizes | 16 x 6.50 - 8 | 16 x 6.50 - 8 |

| Fuel consumption | 1 l/h | 1 l/h |

| Packing sizes | 1330*722*1000.0 mm | 4.36*2,37*3.28 ft |

DETAILS

CLOSEThe mobile wood chipper shredder with autonomous electric drive is designed for chipping dry and green wood up to 10 cm in diameter and is equipped with a silent electric mobility system. The machine can be easily moved in gardens, parks and agricultural environments without the need for tractors or towing vehicles.

GENERAL DESCRIPTION

This machine has been developed to combine a professional chipping system with an innovative transport solution, allowing the wood chipper to be moved completely silently even on uneven terrain or in confined spaces. It is a unique solution on the market, intended for operators who require high cutting performance together with maximum mobility and operational convenience.

DRUM CHIPPING SYSTEM

The cutting system is based on a high-inertia central drum with a width of 300 mm and a diameter of 230 mm, equipped with 2 reversible 300 mm blades made of high-strength special steel, combined with a fixed counter-blade. This configuration ensures a clean, continuous and uniform cut, providing consistent and regular chip production on both dry and green wood.

CHIP DISCHARGE

The machine is equipped with a high, adjustable discharge chute designed to efficiently direct the wood chips into bins, trailers or compost containers. The discharge height facilitates chip collection operations, including loading onto transport vehicles.

APPLICATIONS

The machine is suitable for chipping:

-

dry wood

-

green wood

-

branches and brushwood

-

pruning residues

-

palm leaves

Maximum chipping diameter: 10 cm.

The produced chips are generally regular, approximately 1 cm in size, depending on the type and moisture content of the processed material. The machine is not suitable for shredding maize, straw, alfalfa or similar herbaceous materials.

ENGINE AND STARTING SYSTEM

The machine is equipped with a 420 cc Loncin engine with electric key start, designed to concentrate all its power on the cutting system. This solution guarantees high performance, operational reliability and continuous operation even under intensive working conditions.

AUTONOMOUS ELECTRIC MOBILITY

The wood chipper is mounted on an integrated four-wheel trolley, with two driven wheels and two pivoting wheels, powered by an electric motor. This configuration allows extremely smooth, precise and silent movements, making the machine particularly suitable for use in gardens, parks and noise-sensitive environments.

STEERING SYSTEM AND CONTROLS

The control systems are located on the two steering handles.

On the right handle are the progressive throttle, forward and reverse drive control and the battery charge status indicator, allowing real-time monitoring of the electric motor autonomy.

On the left handle there is the speed selector, allowing the operator to choose between:

-

Speed 1 (slow): 3 km/h

-

Speed 2 (fast): 6 km/h

In reverse gear, the speed is automatically limited to slow mode at 3 km/h, ensuring greater safety and control during manoeuvres.

CONTROL PANEL

At the base of the trolley there is a complete control panel including:

-

hour meter

-

key switch ON / OFF

-

reverse gear indicator light

-

operating mode selector with three positions:

-

ON chipping

-

ON charging or movement

-

OFF switched off

-

TERRAIN ADAPTATION AND STABILITY

The axle on which the two pivoting wheels on the operator side are mounted is of a floating type, thanks to a central pivot that allows the machine to follow the terrain profile even on uneven surfaces. The arrangement of the main weight components, particularly the combustion engine and the electric motor, has been designed to achieve a very low centre of gravity, improving stability, traction and safety during chipping and movement.

POWER SUPPLY AND AUTONOMY

Electric mobility is powered by a 12 V / 20 Ah battery. The autonomy at maximum continuous speed is approximately 90 minutes; under normal, non-continuous operating conditions, this allows a full working day without the need to recharge the battery.

Indicative charging time is approximately 4 hours using a standard 220 V domestic power supply.

SAFETY

The machine is equipped with a mushroom-type emergency stop button that immediately shuts down the engine in case of emergency. A safety sensor prevents the wood chipper engine from starting if the discharge chute is removed. The feed hopper can also be folded, preventing the cutting system from being exposed when the machine is parked or during transport.

BATTERY MANAGEMENT AND EMERGENCY MOVEMENT

If the batteries become discharged during field operation, the wheels can be released, allowing the machine to be pushed or towed manually to the vehicle or charging point.

CERTIFICATIONS – WARRANTY – SERVICE

Machine compliant with CE regulations and equipped with safety protections

2-year warranty

DELEKS® technical support and spare parts availability

SUPPLIED DOCUMENTATION

CE declaration of conformity

User and maintenance manual

Invoice or fiscal receipt

CHARACTERISTICS

CLOSE| Characteristic | Units metric | Units US |

|---|---|---|

| Weight | 230.0 kg | 507.0 lb |

| Blades: Weight | 600.0 g | 21.16 oz |

| Transmission | V Belts | V Belts |

| Working Efficiency | 6-7 m3/h | 19.70-23.0 sq ft/h |

| Cutting System | Chipping drum with 2 blades + 1 fixed blade | Chipping drum with 2 blades + 1 fixed blade |

| Chipped material size range | 1.0 cm | 0.40 in |

| Transmission V-Belts quantity | 2 | 2 |

| Transmission V-Belts sizes | A69 - 1752x13 | A69 - 1752x13 |

| Safety System | Emergency button | Emergency button |

| Blades: Sizes | 300.0*54.0 mm | 11.81*2.16 in |

| Maximum cutting diameter | 80.0 - 100.0 mm | 4.00 in |

| Engine | Loncin 420cc 14cv | Loncin 420cc 14cv |

| Starter | E-start and Pull cord | E-start and Pull cord |

| Wheels: sizes | 16 x 6.50 - 8 | 16 x 6.50 - 8 |

| Fuel consumption | 1 l/h | 1 l/h |

| Packing sizes | 1330*722*1000.0 mm | 4.36*2,37*3.28 ft |