DELEKS S.r.l.

Via Industriale, 23

25028 Verolanuova (BS) Italy

Tel. 030 6585725

Mail info@deleks.com

Lun - Ven: 9.00-13.00 / 14.00-18.00

Drum-type tracked wood chipper with combustion engine

DETAILS

Tracked drum wood chipper designed for chipping dry and green wood up to 10 cm in diameter, engineered to operate safely on uneven and sloping terrain. The tracked drive system and particularly low center of gravity make this machine ideal for professional use in agriculture, forestry and green area maintenance.

GENERAL DESCRIPTION

The tracked wood chipper combines a professional chipping system with an autonomous tracked undercarriage, offering an effective solution for working in hard-to-reach areas, slopes and uneven ground. Unlike other tracked chippers or tracked carrier-mounted chippers in the same category, this model keeps both engines positioned low, significantly improving overall stability.

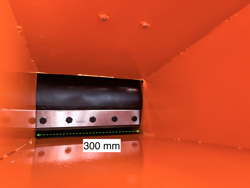

DRUM CHIPPING SYSTEM

The cutting system is based on a high-inertia central drum with a width of 300 mm and a diameter of 230 mm. The drum is equipped with 2 reversible 300 mm blades made of high-strength special steel, combined with a fixed counter-blade. This configuration ensures a clean, continuous and uniform cut, providing consistent chip production on both dry and green wood.

CHIPPING ENGINE

The machine is equipped with a 420 cc Loncin engine with electric key start, concentrating all its power on the cutting system. The engine ensures high torque, reliability and continuous operation even during prolonged and demanding working sessions.

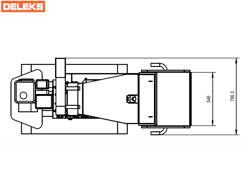

TRACKED DRIVE SYSTEM

Machine movement is handled by a tracked undercarriage powered by a 196 cc Loncin engine. The system features a mechanical gearbox with 3 forward gears and 1 reverse gear, allowing the operator to adapt travel speed to terrain conditions and working requirements. The tracked drive guarantees constant traction and control, even on uneven or sloped surfaces.

TERRAIN ADAPTATION AND STABILITY

The low-mounted configuration of both engines results in an exceptionally low center of gravity, significantly reducing the risk of tipping compared to competing solutions. The machine naturally follows ground contours, ensuring stability and safety during maneuvers and operation on slopes.

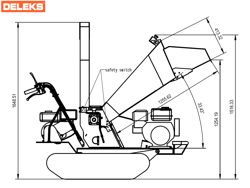

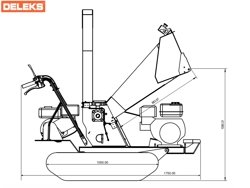

FEED HOPPER AND OVERALL DIMENSIONS

The feed hopper is designed to facilitate material intake and is foldable, allowing a reduction in overall machine length during transport. Despite the tracked undercarriage, the total length during transfers remains comparable to competing models, facilitating transport and maneuvering in confined spaces.

CHIP DISCHARGE

The machine is equipped with a high, adjustable discharge chute designed to efficiently direct the wood chips into bins, trailers or compost containers. The discharge height facilitates chip collection operations, including loading onto transport vehicles.

SAFETY

The wood chipper is equipped with an emergency mushroom-type stop device, allowing immediate shutdown of the cutting system when required. The feed hopper can be folded closed, preventing exposure of the cutting system when the machine is parked or transported. All protective systems are designed to comply with current safety regulations.

APPLICATIONS

The machine is suitable for chipping:

-

dry wood

-

green wood

-

branches and brushwood

-

pruning residues

-

palm leaves

Maximum chipping diameter: 10 cm.

The produced chips are generally regular, approximately 1 cm in size, depending on the type and moisture content of the processed material. The machine is not suitable for shredding maize, straw, alfalfa or similar herbaceous materials.

CERTIFICATIONS – WARRANTY – SUPPORT

Machine compliant with CE regulations and equipped with safety protections

2-year warranty

DELEKS® technical support and spare parts availability

SUPPLIED DOCUMENTATION

CE declaration of conformity

User and maintenance manual

Invoice or fiscal receipt

CHARACTERISTICS

| Characteristic | Units metric | Units US |

|---|---|---|

| Weight | 242.0 kg | 533.0 lb |

| Blades: Weight | 600.0 g | 21.16 oz |

| Transmission | V Belts | V Belts |

| Working Efficiency | 6-7 m3/h | 19.70-23.0 sq ft/h |

| Cutting System | Chipping drum with 2 blades + 1 fixed blade | Chipping drum with 2 blades + 1 fixed blade |

| Chipped material size range | 1.0 cm | 0.40 in |

| Transmission V-Belts quantity | 2 | 2 |

| Transmission V-Belts sizes | A69 - 1752x13 | A69 - 1752x13 |

| Safety System | Emergency button | Emergency button |

| Blades: Sizes | 300.0*55.0 mm | 11.81*2.16 in |

| Maximum cutting diameter | 80.0 - 100.0 mm | 4.00 in |

| Engine | Loncin 420cc + Loncin 196cc | Loncin 420cc + Loncin 196cc |

| Starter | E-start and Pull cord | E-start and Pull cord |

| Fuel consumption | 1 l/h | 1 l/h |

| Packing sizes | 1850*850*1600.0 mm | 6.00*2.80*5.25 ft |

DETAILS

CLOSETracked drum wood chipper designed for chipping dry and green wood up to 10 cm in diameter, engineered to operate safely on uneven and sloping terrain. The tracked drive system and particularly low center of gravity make this machine ideal for professional use in agriculture, forestry and green area maintenance.

GENERAL DESCRIPTION

The tracked wood chipper combines a professional chipping system with an autonomous tracked undercarriage, offering an effective solution for working in hard-to-reach areas, slopes and uneven ground. Unlike other tracked chippers or tracked carrier-mounted chippers in the same category, this model keeps both engines positioned low, significantly improving overall stability.

DRUM CHIPPING SYSTEM

The cutting system is based on a high-inertia central drum with a width of 300 mm and a diameter of 230 mm. The drum is equipped with 2 reversible 300 mm blades made of high-strength special steel, combined with a fixed counter-blade. This configuration ensures a clean, continuous and uniform cut, providing consistent chip production on both dry and green wood.

CHIPPING ENGINE

The machine is equipped with a 420 cc Loncin engine with electric key start, concentrating all its power on the cutting system. The engine ensures high torque, reliability and continuous operation even during prolonged and demanding working sessions.

TRACKED DRIVE SYSTEM

Machine movement is handled by a tracked undercarriage powered by a 196 cc Loncin engine. The system features a mechanical gearbox with 3 forward gears and 1 reverse gear, allowing the operator to adapt travel speed to terrain conditions and working requirements. The tracked drive guarantees constant traction and control, even on uneven or sloped surfaces.

TERRAIN ADAPTATION AND STABILITY

The low-mounted configuration of both engines results in an exceptionally low center of gravity, significantly reducing the risk of tipping compared to competing solutions. The machine naturally follows ground contours, ensuring stability and safety during maneuvers and operation on slopes.

FEED HOPPER AND OVERALL DIMENSIONS

The feed hopper is designed to facilitate material intake and is foldable, allowing a reduction in overall machine length during transport. Despite the tracked undercarriage, the total length during transfers remains comparable to competing models, facilitating transport and maneuvering in confined spaces.

CHIP DISCHARGE

The machine is equipped with a high, adjustable discharge chute designed to efficiently direct the wood chips into bins, trailers or compost containers. The discharge height facilitates chip collection operations, including loading onto transport vehicles.

SAFETY

The wood chipper is equipped with an emergency mushroom-type stop device, allowing immediate shutdown of the cutting system when required. The feed hopper can be folded closed, preventing exposure of the cutting system when the machine is parked or transported. All protective systems are designed to comply with current safety regulations.

APPLICATIONS

The machine is suitable for chipping:

-

dry wood

-

green wood

-

branches and brushwood

-

pruning residues

-

palm leaves

Maximum chipping diameter: 10 cm.

The produced chips are generally regular, approximately 1 cm in size, depending on the type and moisture content of the processed material. The machine is not suitable for shredding maize, straw, alfalfa or similar herbaceous materials.

CERTIFICATIONS – WARRANTY – SUPPORT

Machine compliant with CE regulations and equipped with safety protections

2-year warranty

DELEKS® technical support and spare parts availability

SUPPLIED DOCUMENTATION

CE declaration of conformity

User and maintenance manual

Invoice or fiscal receipt

CHARACTERISTICS

CLOSE| Characteristic | Units metric | Units US |

|---|---|---|

| Weight | 242.0 kg | 533.0 lb |

| Blades: Weight | 600.0 g | 21.16 oz |

| Transmission | V Belts | V Belts |

| Working Efficiency | 6-7 m3/h | 19.70-23.0 sq ft/h |

| Cutting System | Chipping drum with 2 blades + 1 fixed blade | Chipping drum with 2 blades + 1 fixed blade |

| Chipped material size range | 1.0 cm | 0.40 in |

| Transmission V-Belts quantity | 2 | 2 |

| Transmission V-Belts sizes | A69 - 1752x13 | A69 - 1752x13 |

| Safety System | Emergency button | Emergency button |

| Blades: Sizes | 300.0*55.0 mm | 11.81*2.16 in |

| Maximum cutting diameter | 80.0 - 100.0 mm | 4.00 in |

| Engine | Loncin 420cc + Loncin 196cc | Loncin 420cc + Loncin 196cc |

| Starter | E-start and Pull cord | E-start and Pull cord |

| Fuel consumption | 1 l/h | 1 l/h |

| Packing sizes | 1850*850*1600.0 mm | 6.00*2.80*5.25 ft |